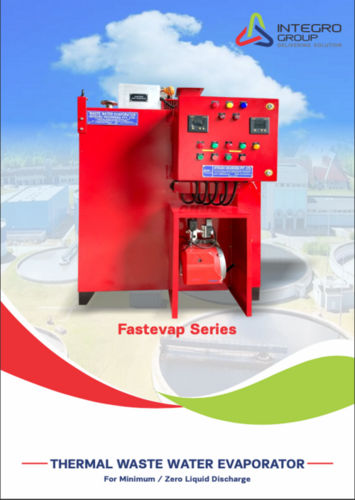

Waste Water Evaporator (Under Products Head)

Price 150000.00 INR/ Unit

Waste Water Evaporator (Under Products Head) Specification

- Weight

- 450 kg

- Voltage

- 380 V / 415 V 3-phase

- Material

- Stainless Steel

- Application

- Industrial Waste Water Treatment

- Function

- Evaporation of waste water to reduce volume

- Membrane Quantity

- As per requirement

- Dimension (L*W*H)

- 1200 x 800 x 1750 mm

- Color

- Silver / Grey

- Capacity

- 100-500 LPH (Liters per hour)

- Lead Time

- 4-8 weeks

- Power

- 8 kW

- Product Type

- Waste Water Evaporator

- Membrane Size

- Customizable

- Control System

- PLC Based

- Evaporation Technology

- Forced Circulation / Falling Film

- Heating Source

- Electric / Steam / Thermal Oil

- Installation Type

- Skid Mounted

- Noise Level

- <75 dB(A)

- Operating Temperature Range

- 40°C to 110°C

- Maximum Concentration Ratio

- Up to 95%

- Manufacturing Standard

- Complies with international industrial standards

- Inlet/Outlet Connection Size

- DN32 / DN50 / DN80 (customizable)

- Automation Grade

- Semi-Automatic / Fully Automatic

- Service Support

- On-site and remote technical support available

- Safety Features

- Overheat protection, Pressure release valves, Emergency stop

Waste Water Evaporator (Under Products Head) Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 1 Days

About Waste Water Evaporator (Under Products Head)

Features:

- Control panels with operator convenience

- Toggle switch provides positive on-off positions for pump operations

- Low and high-level sensors with high-temperature control and manual reset high limit override

Technical Specifications

|

Dimension |

73" L x 35" W x 77" H |

|

Body Material |

Mild Steel / SS |

|

Motor Horsepower |

500 LPD |

|

Voltage |

440 V |

|

Water Source |

Industrial Effluent |

|

Installation Service |

Yes |

|

Brand/Make |

Integro |

|

Country of Origin |

Made in India |

|

Vent Stack |

16" Diameter |

|

Tank Height |

54" |

|

Tank Capacity |

375 Gallons |

|

Power |

15 kW |

Specification

- Size: 45 lts /hr to 300 ltrs /hr

- Electrical / Gas/ Sream operated.

- MOC : SS316 / MS

Advanced Evaporation Technologies

Utilizing Forced Circulation and Falling Film evaporation methods, our system delivers consistent and efficient performance for industrial waste water treatment. These technologies enable high concentration ratios of up to 95%, making the process effective in volume reduction and resource recovery.

Robust Construction and Safety

Fabricated with stainless steel and assembled to international industrial standards, the evaporator stands out for durability. Safety features include overheat protection, pressure release valves, and emergency stop, ensuring secure operation across all usage scenarios.

User-Friendly Automation and Control

The evaporator is available in both semi-automatic and fully automatic models, supported by a PLC-based control system that simplifies operation and monitoring. Skid-mounted installation further streamlines setup and maintenance, while remote and on-site service support maximize uptime.

FAQs of Waste Water Evaporator (Under Products Head):

Q: How does the Waste Water Evaporator help in reducing industrial waste water volume?

A: The evaporator operates by heating and circulating waste water, causing water molecules to evaporate while concentrating solid residues. This process efficiently reduces the liquid volume of waste water by up to 95%, aiding proper disposal and minimizing storage or transportation requirements.Q: What evaporation technologies are used in this system and what are their advantages?

A: This product employs Forced Circulation and Falling Film evaporation technologies. Forced Circulation ensures high turbulence for better heat exchange, while Falling Film provides efficient evaporation at moderate temperatures, both contributing to improved concentration performance and energy savings.Q: Where can this evaporator be installed, and is it suitable for compact spaces?

A: With its skid-mounted design and compact dimensions (1200 x 800 x 1750 mm), the evaporator is suitable for installation in various industrial environments, including facilities with limited space. Its modular setup enables easy integration into existing water treatment infrastructure.Q: What are the available options for heating sources and can the system be customized?

A: Customers can select from electric, steam, or thermal oil heating sources depending on their application and energy preferences. Additionally, connections, membrane sizes, and quantities are customizable to meet specific process requirements.Q: How is the system controlled and what automation levels are offered?

A: Control is managed through a PLC-based system, ensuring precise monitoring and adjustment of operating parameters. The evaporator can be configured as either semi-automatic or fully automatic, providing operational flexibility for users.Q: What safety features are integrated in the Waste Water Evaporator?

A: Safety mechanisms include overheat protection, pressure release valves, and an emergency stop function, all designed to prevent accidents and ensure secure operation during both routine and emergency situations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wastewater Evaporator Category

Wastewater Evaporator 500 LPD

Price 345000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Application : ETP / RO reject

Product Type : Wastewater Evaporator 500 LPD

Material : As Per Requirement

Color : Red

lndustrial Wastewater Treatment Evaporator

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial

Product Type : lndustrial Wastewater Treatment Evaporator

Material : Mild Steel

Color : Red

Wastewater Evaporator System

Price 250000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial

Product Type : Wastewater Evaporator System

Material : Mild Steel

Color : Red

Industrial Waste Water Evaporator

Price 350000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial

Product Type : Industrial Waste Water Evaporator

Material : Mild Steel

Color : Red

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free